9 月 . 02, 2024 14:15 Back to list

High-Quality Galvanized Malleable Iron Tee Factory - Durable & Reliable

Understanding 3% 204% in Galvanized Malleable Iron Tee Manufacturing

Galvanized malleable iron tees are essential components in various industries, known for their durability and versatility in plumbing, gas, and construction applications. Among the many specifications that define these products, the terms 3% 204% signify important composition and performance metrics that manufacturers must adhere to in their production processes. In this article, we will explore what these figures mean and their significance in the manufacturing of galvanized malleable iron tees.

Composition of Malleable Iron

Malleable iron is a type of cast iron that has been heat-treated to enhance its ductility and strength. The term malleable itself indicates that the material can be shaped and bent without breaking, making it ideal for fittings like tees. The “3%” and “204%” refer to specific parameters relevant to the material's composition and mechanical properties.

The designation 3% typically pertains to the percentage of carbon content present in the iron, which plays a crucial role in determining the iron's hardness and brittleness. A 3% carbon content ensures that the iron maintains a balance between strength and malleability. In practical terms, this means that the galvanized malleable iron tees produced with this composition will be strong enough to handle various pressures and stresses without failing.

The Significance of 204%

The “204%” often refers to the elongation percentage of the malleable iron after it undergoes a tensile test. Elongation is a measure of how much a material can stretch before breaking and is crucial for malleable iron tees, which need to withstand bending and twisting forces in real-world applications. A 204% elongation indicates that the material is exceptionally reliable and able to deform significantly before arriving at its breaking point. This makes it an excellent choice for industrial applications where flexibility and resilience are critical.

Manufacturing Processes

3 4 in galvanized malleable iron tee factory

The manufacturing of galvanized malleable iron tees involves several key steps

1. Casting The first step is melting iron and pouring it into molds to create the desired tee shape. This is usually done in a foundry, where operators ensure that the correct composition is maintained.

2. Heat Treatment The cast tees are then subjected to heat treatments to achieve the necessary malleability. This process also reinforces their mechanical properties.

3. Galvanizing After the tees are cooled, they undergo galvanization, where a protective layer of zinc is applied to prevent rust and corrosion. This is particularly important for tees that will be used in plumbing or outdoor applications.

4. Quality Assurance Finally, each batch undergoes rigorous quality checks to ensure compliance with industry standards, including tests for tensile strength and elongation.

Conclusion

In summary, the specifications 3% 204% in galvanized malleable iron tees represent critical aspects of their composition and performance, influencing their applications across numerous industries. Understanding these metrics not only helps manufacturers produce high-quality products but also informs consumers of the reliability and durability they can expect. As industries continue to evolve, the demand for robust and adaptable materials like galvanized malleable iron tees will only grow, highlighting the importance of precision and quality in manufacturing practices.

-

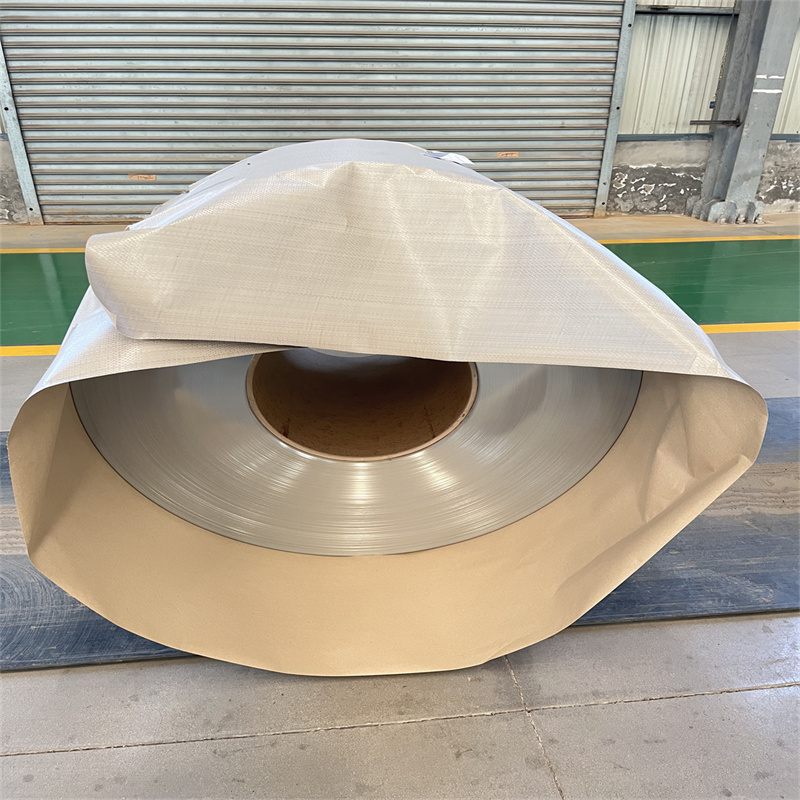

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

buy corrugated roof sheet end capping

NewsMar.07,2025