10 月 . 02, 2024 01:18 Back to list

Black Iron and Galvanized Iron Production Facilities Overview and Industry Insights

Black Iron and Galvanized Iron Factories A Comprehensive Overview

The production of iron, particularly in its varied forms, is a crucial aspect of modern manufacturing and construction. Among the different types of iron, black iron and galvanized iron stand out for their unique properties and applications. Understanding the factories that produce these materials sheds light on the industrial processes and the significance of these metals in various sectors.

Black iron, characterized by its raw, uncoated surface, is primarily used in applications where corrosion resistance is not a concern. It is often utilized in the manufacturing of construction materials, pipes, and fixtures. The production of black iron involves a series of processes, including smelting, refining, and shaping. Factories specializing in black iron typically focus on the melting and casting of iron ores, followed by forging and rolling to achieve the desired shapes and sizes. The quality of black iron is critical, as it needs to withstand significant stress and strain in construction scenarios.

In contrast, galvanized iron is known for its superior durability and corrosion resistance, making it a preferred choice for outdoor and industrial applications. The galvanization process involves coating black iron with a layer of zinc, which acts as a protective barrier against rust and environmental damage. Factories that produce galvanized iron employ several methods of galvanization, most commonly hot-dip galvanization, where the iron is submerged in molten zinc. This method ensures that the zinc penetrates every crevice of the iron surface, providing robust protection.

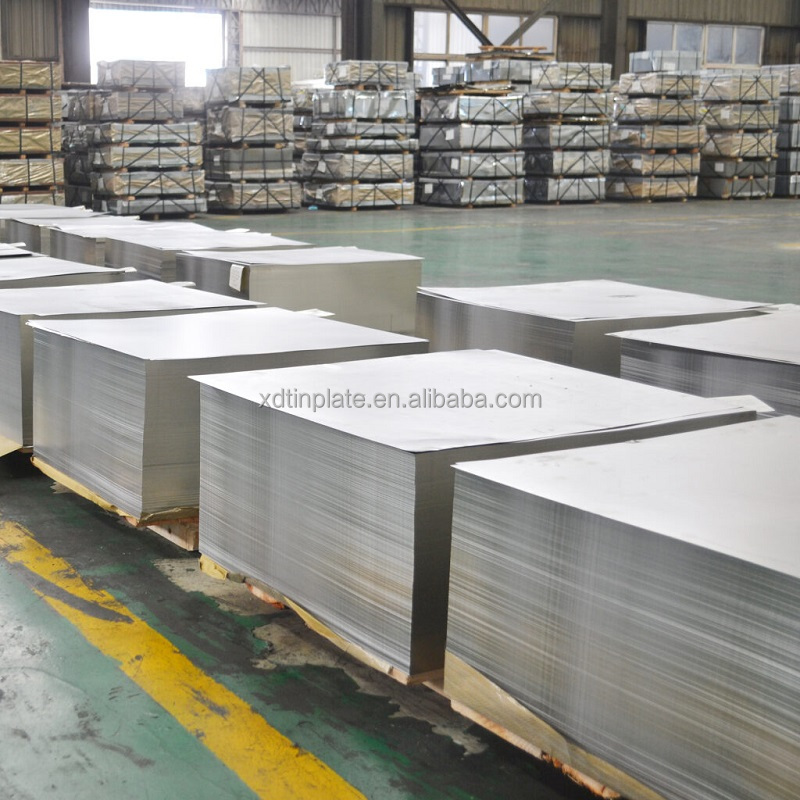

black iron galvanized iron factories

The production facilities for galvanized iron require advanced technology and strict quality control measures to ensure the zinc coating’s integrity. This process not only enhances the lifespan of the iron but also reduces maintenance costs for the end-user. These factories are often equipped with specialized machinery and automated systems that enhance efficiency and reduce labor costs.

Furthermore, both black iron and galvanized iron factories play a significant role in the local economy. They provide numerous jobs and contribute to the supply chain for various industries, including construction, automotive, and manufacturing. With the increasing demand for sustainable practices, many factories are now also focusing on recycling and reducing waste in their production processes.

In conclusion, black iron and galvanized iron factories are integral to the industrial landscape. They produce materials that are fundamental to construction and manufacturing, with each type of iron serving its unique purposes. As technology advances and environmental concerns grow, these factories will continue to evolve, adopting new techniques and practices to meet the changing demands of the industry while maintaining quality and efficiency. The future of iron production looks promising, with innovations that may further enhance the properties of these essential materials.

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

buy corrugated roof sheet end capping

NewsMar.07,2025