10 月 . 13, 2024 01:59 Back to list

EPDM Rubber Roofing Sheet Manufacturers and Suppliers Guide

EPDM Rubber Roof Sheet Factories An Overview

In the construction industry, roofing materials play a crucial role in determining the longevity and durability of a building. Among various roofing solutions available, EPDM (Ethylene Propylene Diene Monomer) rubber roof sheets have gained immense popularity due to their outstanding properties and versatility. This article delves into the world of EPDM rubber roof sheet factories, exploring their significance, manufacturing processes, and benefits.

Understanding EPDM Rubber

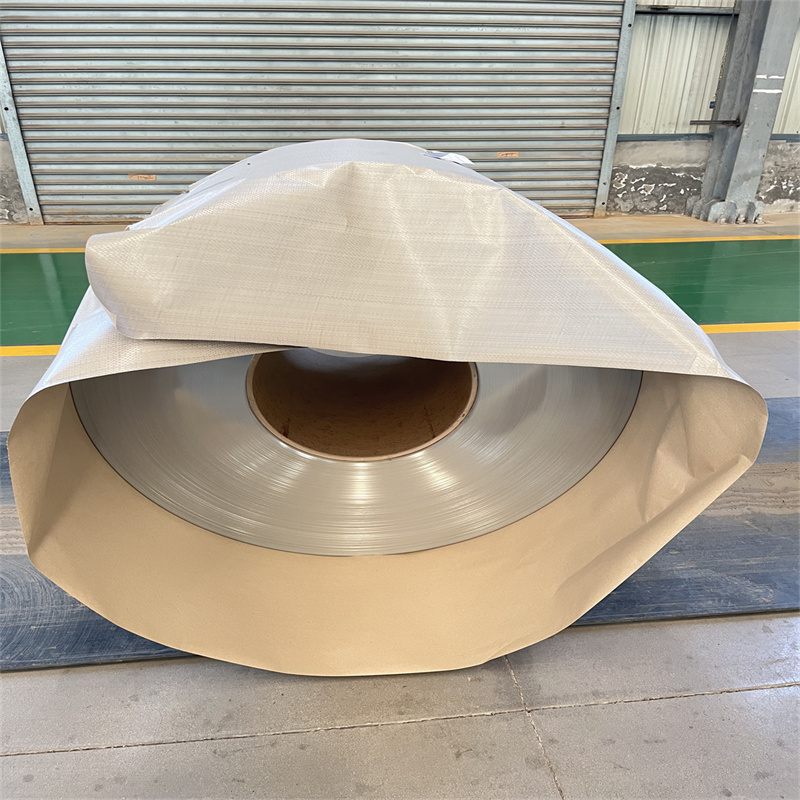

EPDM is a synthetic rubber that possesses remarkable resistance to UV radiation, ozone, and extreme weather conditions. With a high degree of elasticity, it can efficiently withstand temperature fluctuations, making it an ideal choice for roofing applications. EPDM roof sheets are typically available in large rolls and can be adhered directly to the roof insulation or mechanically fastened, providing flexibility in installation based on the specific requirements of the building.

The Role of EPDM Rubber Roof Sheet Factories

Factories producing EPDM rubber roof sheets are pivotal in meeting the rising demand for durable and sustainable roofing solutions. These manufacturing units implement advanced technologies and innovative techniques to ensure high-quality output. The factories employ skilled workers who manage the production lines and maintain quality control, ensuring that every sheet meets industry standards.

The manufacturing process begins with the mixing of raw materials. The primary components of EPDM include ethylene, propylene, and a small percentage of diene monomer, which contributes to the material's properties. This careful blending is crucial for achieving the desired performance characteristics of the rubber sheets, such as strength, flexibility, and resistance to aging.

Once the materials are mixed, they undergo a process called calendaring, where the mixture is rolled out into sheets of various thicknesses. These sheets are then cured through a process known as vulcanization, which enhances their resilience and longevity. After curing, the sheets are inspected for quality, ensuring that they meet all specifications before being packaged for shipping.

epdm rubber roof sheet factories

Benefits of EPDM Rubber Roof Sheets

1. Durability EPDM rubber roof sheets can last for up to 50 years with proper maintenance, making them a cost-effective long-term roofing solution. Their ability to resist cracking, peeling, and shrinkage is essential for ensuring a well-protected building.

2. Energy Efficiency These roof sheets can be manufactured in reflective colors, which help in reducing heat absorption, thereby lowering energy costs associated with air conditioning during hot months. This aspect significantly contributes to a building’s overall energy efficiency.

3. Ease of Installation EPDM sheets are lightweight and can be installed with relative ease compared to traditional roofing materials. Their compatibility with various roofing systems allows for versatility in applications, whether for residential, commercial, or industrial buildings.

4. Environmentally Friendly Many EPDM manufacturers prioritize sustainability by using recycled materials in their products and adopting eco-friendly manufacturing practices. EPDM roofs can also be recycled at the end of their life cycle, making them a responsible choice for environmentally-conscious builders.

5. Low Maintenance Once installed, EPDM roofs require minimal maintenance. Regular inspections and occasional cleaning can ensure their longevity without the need for extensive repairs, providing significant savings in upkeep costs over time.

Conclusion

EPDM rubber roof sheet factories play a vital role in the production of one of the most efficient roofing solutions available today. With their advanced manufacturing processes and commitment to quality, these factories contribute to the durability, energy efficiency, and overall performance of buildings. As the construction industry increasingly focuses on sustainable practices, EPDM rubber roof sheets stand out as a reliable choice for both commercial and residential applications. For anyone considering roofing options, understanding the benefits of EPDM and the role of its manufacturing can pave the way for informed decisions that enhance building performance and sustainability.

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

buy corrugated roof sheet end capping

NewsMar.07,2025