9 月 . 01, 2024 11:18 Back to list

High-Quality Galvanized Color Coating Plant Manufacturer

Understanding the Galvanized Color Coating Plant A Key Element in Manufacturing

In the industrial landscape, the galvanized color coating plant plays a pivotal role in the manufacturing of metal products, particularly in enhancing the durability and aesthetic appeal of steel and other metals. This specialized facility is designed to apply a protective and decorative layer of paint or coating to galvanized materials, ensuring they withstand environmental challenges while maintaining their visual attractiveness.

The Process of Galvanization and Coating

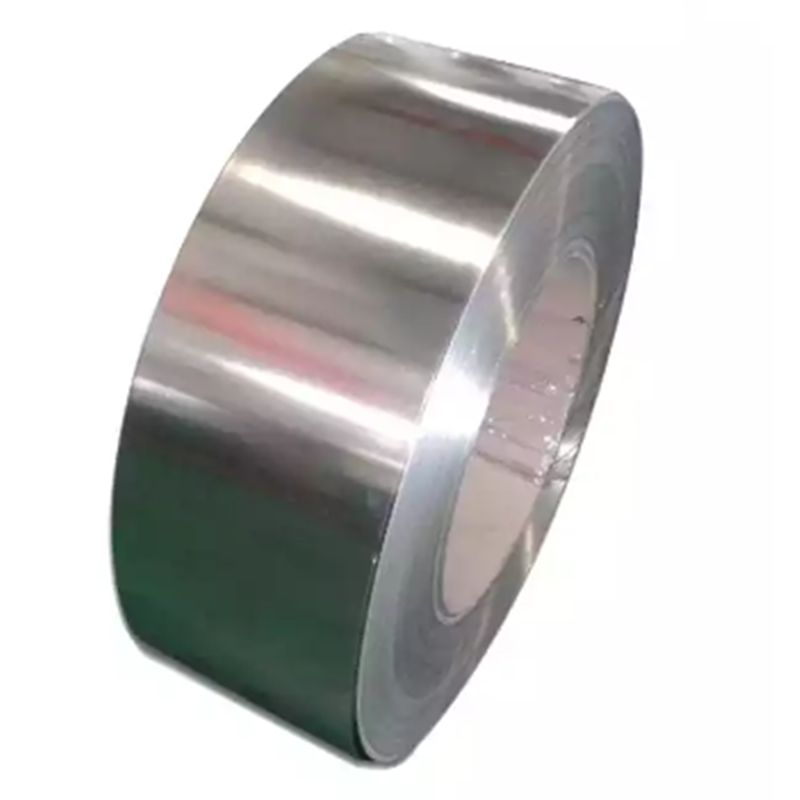

Galvanization involves the application of a zinc coating to iron or steel to protect it from corrosion. This process is essential for extending the lifespan of metal structures and components. However, to meet consumer demands for a variety of colors and finishes, galvanized products often undergo additional processing at a coating plant. The color coating process typically includes surface preparation, application of the coating material, and curing.

1. Surface Preparation Before any coating can be applied, the galvanized surface must be thoroughly cleaned and prepared. This may involve washing, sanding, or chemical treatments to remove any contaminants or irregularities that could affect adhesion. 2. Coating Application After preparation, the next step is the application of the color coating. Advanced techniques such as electrostatic spraying, powder coating, or liquid spray painting are commonly used. The choice of application method depends on factors such as the desired finish, production volume, and environmental considerations.

3. Curing Once the coating has been applied, the products undergo a curing process to harden the finish and promote adhesion. This is often achieved through heat treatment, where the coated items are passed through an oven at controlled temperatures.

galvanized color coating plant factory manufacturer

Advantages of Galvanized Color Coating

The benefits of using a galvanized color coating plant extend beyond mere aesthetics. The combined processes of galvanization and color coating provide enhanced protection against rust, wear, and ultraviolet radiation. Consumers can expect longer-lasting products, which translates to lower maintenance costs over time. Additionally, color coatings can be customized, allowing manufacturers to offer a wide range of options to meet specific customer preferences.

Moreover, the eco-friendly advancements in coating technologies, such as water-based coatings, have made it possible to reduce environmental impact while still achieving exceptional quality in finishes. Companies are increasingly adopting sustainable practices, aligning their operations with global standards.

Conclusion

The galvanized color coating plant embodies the intersection of technology, sustainability, and consumer demand in modern manufacturing. As industries continue to evolve, the significance of these facilities will only grow, underscoring the importance of quality coatings in producing durable, visually appealing products. For manufacturers looking to enhance their production capabilities and meet market trends, investing in a galvanized color coating plant is not just a strategic move; it’s a necessity for future competitiveness.

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

buy corrugated roof sheet end capping

NewsMar.07,2025