9 月 . 16, 2024 05:35 Back to list

galvanized iron coating suppliers

The Role of Galvanized Iron Coating Suppliers in Modern Infrastructure

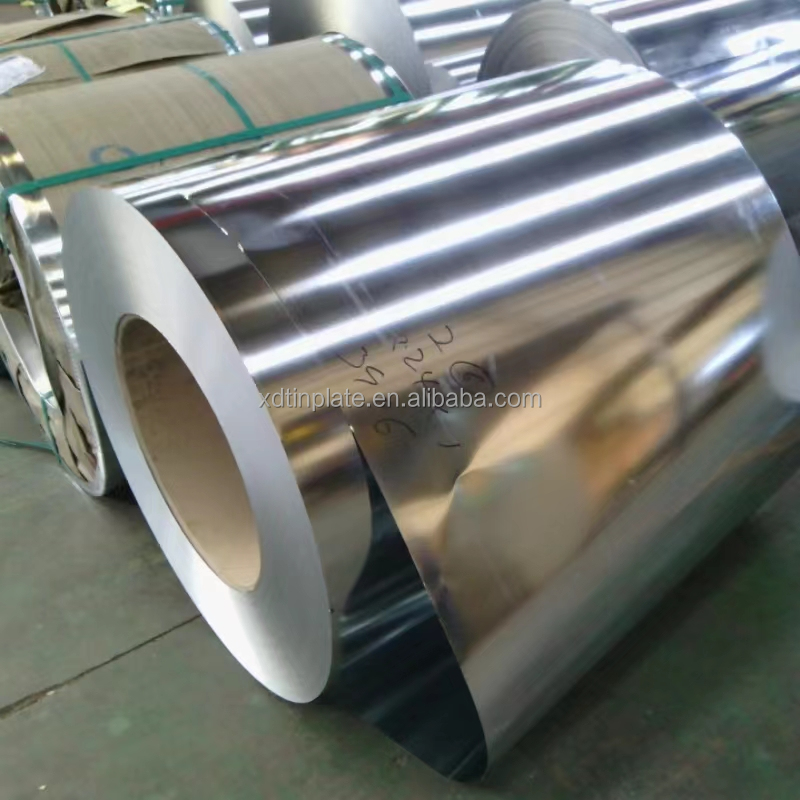

Galvanized iron has emerged as a cornerstone material in various industries, particularly in construction and manufacturing. The process of galvanization, which involves coating iron or steel with a layer of zinc, provides a significant protective barrier against corrosion, extending the lifespan of metal structures and products. This has led to an increased demand for galvanized iron coating suppliers, who play a pivotal role in ensuring the quality and availability of this vital material.

One of the primary advantages of galvanized iron is its durability. The zinc coating acts as a sacrificial anode; even when the coating is scratched or damaged, the zinc continues to protect the underlying iron from corroding. This characteristic makes galvanized iron an ideal choice for outdoor applications, including roofing, fencing, and various structural components that are exposed to the elements. As industries increasingly prioritize sustainability and longevity, the role of galvanized iron coating suppliers has become even more critical.

A reputable galvanized iron coating supplier offers a range of services and products that meet the diverse needs of customers. They ensure that the galvanization process adheres to international standards, providing a consistent and high-quality product that clients can rely on. Additionally, these suppliers often engage in continuous research and development to improve the galvanization process, enhancing the material's performance against adverse environmental conditions.

galvanized iron coating suppliers

In addition to product quality, galvanized iron coating suppliers must also focus on customer service. Understanding the unique requirements of each client allows suppliers to recommend the most suitable products and solutions. Many suppliers provide customized services, such as tailored coating thicknesses and specialized treatments for different applications, ensuring that clients receive exactly what they need. This level of attention and adaptability can significantly enhance client satisfaction and loyalty.

The competition among galvanized iron coating suppliers is also shaping the market. With several suppliers vying for the attention of businesses, many are now adopting advanced technologies to streamline their operations. Automation, for instance, enhances efficiency, reduces production costs, and minimizes human error, thereby improving the overall quality of the galvanized products. Digital platforms are also playing a role in how suppliers interact with customers by facilitating easier ordering processes and improving transparency regarding product availability and specifications.

Furthermore, galvanized iron coating suppliers are becoming increasingly aware of the environmental impact of their operations. Many are striving to incorporate eco-friendly practices in their processes, such as utilizing non-toxic chemicals in treatments and opting for sustainable energy sources in production. This not only helps in reducing the carbon footprint of galvanized iron products but also aligns with the global push towards greener industries.

In conclusion, the role of galvanized iron coating suppliers is indispensable in modern infrastructure. By providing high-quality, durable, and sustainable galvanized iron products, these suppliers not only enhance the longevity of metal structures but also contribute to the overall progress of construction and manufacturing industries. As demand continues to grow, the importance of choosing the right supplier will be paramount for businesses seeking to invest in reliable and environmentally friendly materials.

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

buy corrugated roof sheet end capping

NewsMar.07,2025