10 月 . 06, 2024 00:31 Back to list

galvanized color coating plant factory manufacturers

Understanding Galvanized Color Coating Plants Manufacturers and Their Impact

In today's industrial landscape, galvanization and color coating serve as essential processes for enhancing the durability and aesthetic appeal of metal products. For manufacturers in various sectors, establishing efficient galvanized color coating plants has become a critical investment. This article explores the significance of these plants and highlights the role of manufacturers in this sector.

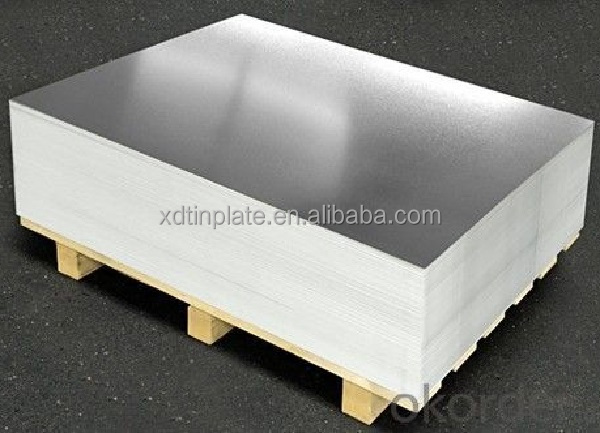

Galvanization is the process of applying a protective zinc coating to steel or iron to prevent rusting and corrosion. This technique significantly extends the lifespan of metal products, making them ideal for outdoor applications. However, raw galvanized steel often lacks visual appeal; therefore, color coating becomes indispensable. By adding a layer of paint or polymer on top of the galvanized surface, manufacturers can provide not only corrosion resistance but also aesthetic enhancements that meet consumer preferences.

When it comes to choosing a galvanized color coating plant manufacturer, several factors come into play. Quality assurance is paramount. Reputable manufacturers adhere to strict international standards to ensure that their coating products exhibit excellent adhesion, durability, and resistance to fading or chipping. Advanced manufacturing processes, including automated spraying and oven curing techniques, contribute to the production of high-quality coated materials.

galvanized color coating plant factory manufacturers

Moreover, innovation in technology is a significant driver in this industry. Many manufacturers are increasingly adopting eco-friendly practices and materials in their processes. This shift not only aligns with global sustainability efforts but also helps companies meet regulatory requirements. The integration of techniques such as powder coating, which produces less waste and does not release harmful solvents, is becoming more common. As a result, manufacturers can offer sustainable products without compromising on performance or quality.

In addition to environmental considerations, manufacturers must also focus on customization. The demand for personalized solutions in various industries, including construction, automotive, and home appliances, is on the rise. Leading manufacturers provide tailored color options and finishes to meet specific client requirements. This flexibility allows customers to differentiate their products in a competitive marketplace.

Furthermore, the importance of after-sales support cannot be overstated. An excellent manufacturer provides comprehensive service packages encompassing installation, maintenance, and troubleshooting. This commitment not only enhances customer satisfaction but also fosters long-term business relationships.

In conclusion, galvanized color coating plants play a pivotal role in modern manufacturing by offering durable and aesthetically pleasing products. For manufacturers, the challenge lies in balancing quality, innovation, and sustainability while meeting the diverse needs of their clients. As technology advances and consumer expectations evolve, those manufacturers that prioritize these elements will lead the way in the industry, paving the path for future developments in galvanized and color-coated products. With a growing emphasis on environmental responsibility and personalization, the landscape of galvanized color coating is set to become even more dynamic and impactful.

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

buy corrugated roof sheet end capping

NewsMar.07,2025