9 月 . 28, 2024 17:41 Back to list

Galvanized Corrugated Steel Sheet Manufacturer with High-Quality Production Standards

The Evolution and Significance of Galvanized Corrugated Steel Sheets A Factory Perspective

In the modern era of construction and manufacturing, galvanized corrugated steel sheets have emerged as a cornerstone material, known for their strength, durability, and versatility. The factory that specializes in the production of these sheets plays a crucial role in the supply chain, catering to various industries, including construction, automotive, and appliances. This article explores the significance of galvanized corrugated steel sheets and the processes involved in their manufacturing.

Understanding Galvanization

Galvanization is a process that involves coating steel with a layer of zinc to prevent rusting and corrosion. The method provides a protective barrier, enhancing the longevity of the steel, which is particularly important in environments exposed to moisture and harsh weather conditions. Galvanized corrugated steel sheets not only fulfill structural requirements but also offer aesthetic appeal, making them a popular choice for roofing and siding applications.

The Production Process

The manufacturing of galvanized corrugated steel sheets involves several critical steps. First, high-quality steel coils are sourced, which are then cleaned and prepared for galvanization. The cleaning process ensures that any contaminants, such as rust or oil, are removed, allowing for an effective zinc coating.

Following cleaning, the steel coils undergo the galvanization process, typically achieved through hot-dip galvanization. In this method, the coils are immersed in a bath of molten zinc, which adheres to the surface of the steel. This coating forms a robust barrier against corrosion, significantly extending the material's lifespan. Once galvanized, the steel sheets are cooled, allowing the zinc to solidify and bond with the steel.

After galvanization, the sheets are molded into their characteristic corrugated shape. This process enhances their structural integrity, allowing the sheets to withstand various loads. The corrugation forms added rigidity and helps maintain the shape under pressure, making them ideal for roofing applications. Factories often use advanced technology and machinery to automate this process, ensuring precision and efficiency.

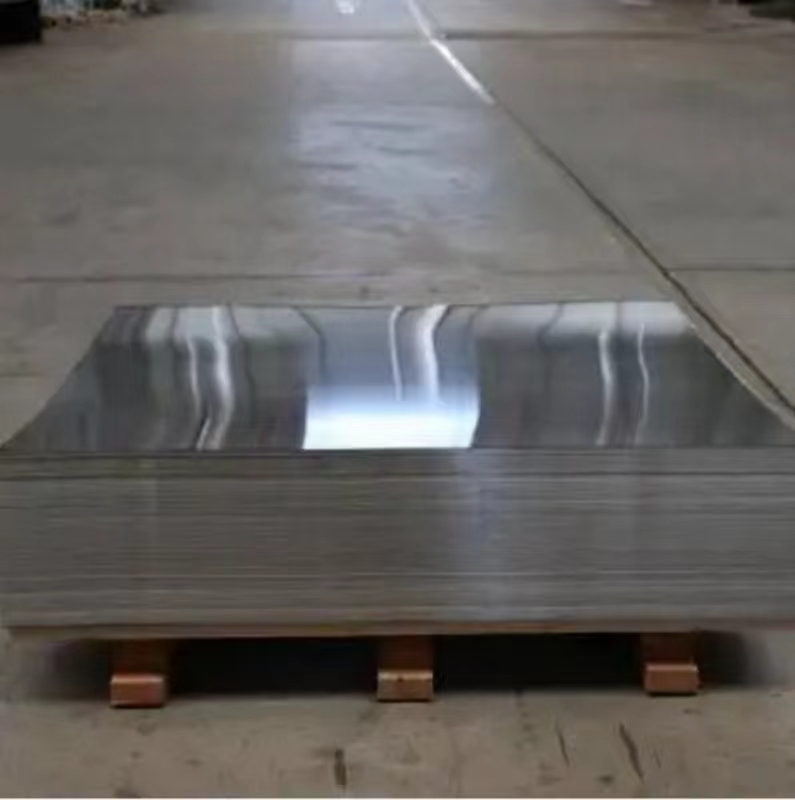

galvanized corrugated steel sheet factory

Applications of Galvanized Corrugated Steel Sheets

The versatility of galvanized corrugated steel sheets lends itself to a wide range of applications. In the construction industry, they are commonly used for roofing, wall cladding, and fencing. Their lightweight nature and easy installation contribute to reduced labor costs and enhanced project timelines.

Moreover, these steel sheets are favored in agricultural settings for building barns, silos, and storage sheds due to their durability and resistance to environmental factors. In the automotive and appliance sectors, manufacturers utilize galvanized steel for car bodies and home appliances, where corrosion resistance is a priority.

Environmental Considerations

As sustainability becomes increasingly important in manufacturing, factories producing galvanized corrugated steel sheets are adopting more eco-friendly practices. The zinc used in the galvanization process is recyclable, and many manufacturers strive to minimize waste during production. Additionally, advancements in technology are leading to more energy-efficient processes, reducing the overall environmental impact of steel production.

Market Trends and Future Outlook

The demand for galvanized corrugated steel sheets is expected to grow, driven by the expansion of the construction and automotive industries, particularly in developing economies. Emerging trends, such as increased urbanization and infrastructure development, will likely continue to fuel this growth. Factories must remain innovative, adapting to market needs and leveraging new technologies to enhance efficiency and product quality.

In conclusion, galvanized corrugated steel sheets produced in factories represent a blend of practicality and resilience. Their widespread use in various applications underscores their significance in modern construction and manufacturing. As industries evolve, the role of galvanized steel will continue to be pivotal, making the factories that produce these materials essential players in the market. The future holds promising opportunities for the galvanized steel industry, with innovation propelling growth and sustainability at its forefront.

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

buy corrugated roof sheet end capping

NewsMar.07,2025