9 月 . 28, 2024 01:46 Back to list

Galvanized Iron Water Pipe Manufacturing Facilities and Their Production Processes

Galvanized Iron Water Pipe Factories A Key Component in Infrastructure Development

Galvanized iron pipes, known for their resilience and durability, play an essential role in water distribution systems globally. These pipes are made of iron that has been coated with a layer of zinc to prevent rusting and corrosion, which significantly extends their lifespan. The process of galvanization ensures that the pipes can withstand harsh weather conditions and exposure to water, making them ideal for various applications, especially in urban infrastructure.

The production of galvanized iron water pipes involves several key steps. First, high-quality iron is sourced and prepared for the galvanization process. This involves cleaning the iron surface to remove any impurities, which is crucial for ensuring a strong bond between the iron and the zinc coating. After cleaning, the pipes are submerged in molten zinc, allowing a metallic bond to form. This process can be achieved through hot-dip galvanization, where the pipes are heated and dipped into molten zinc, or electro-galvanization, where an electric current helps in the deposition of zinc onto the iron surface.

The factories producing galvanized iron water pipes are equipped with advanced machinery and technology to ensure high-quality output

. Automated systems monitor the galvanization process, maintaining consistent thickness and quality of the zinc coating. This industrial efficiency not only boosts production rates but also meets the stringent standards set by regulatory bodies for construction materials.galvanized iron water pipe factories

Moreover, galvanized iron water pipes are favored for their versatility. They can be used in various environments, from residential plumbing to large-scale municipal projects. Their ability to resist rust makes them suitable for transporting not only potable water but also sewage and industrial liquids. As global awareness of water conservation and infrastructure sustainability grows, the demand for durable materials like galvanized iron pipes continues to rise.

In recent years, galvanized iron water pipe factories have also made strides toward more environmentally friendly practices. Innovations in production have reduced waste and energy consumption, aligning with sustainable development goals. Furthermore, many factories are now focusing on recycling and reusing materials, minimizing the environmental impact associated with traditional manufacturing processes.

In conclusion, galvanized iron water pipe factories are crucial players in the development of sustainable infrastructure. With their robust production processes and commitment to quality, these factories contribute significantly to reliable water distribution systems worldwide. As urbanization continues to expand, the importance of such factories will only increase, highlighting their vital role in ensuring safe and efficient water supply for future generations.

-

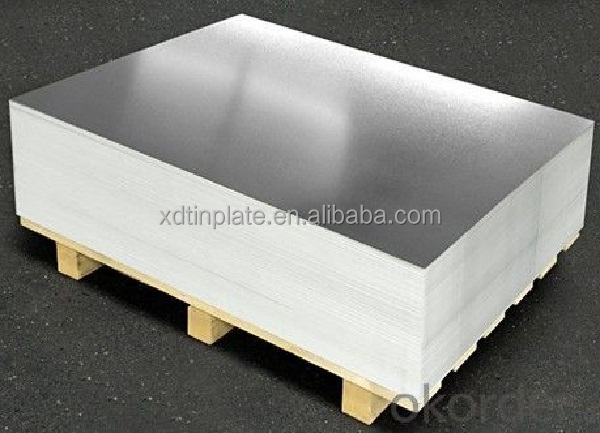

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

buy corrugated roof sheet end capping

NewsMar.07,2025