9 月 . 23, 2024 01:52 Back to list

lunch box tin manufacturer

The Evolution and Impact of Lunch Box Tin Manufacturers

In the world of manufacturing, few items have stood the test of time quite like the lunch box. From its humble beginnings as a simple container for food to its status as a cultural icon, the lunch box has evolved dramatically over the years. Among the various materials used in the production of lunch boxes, tin has played a prominent role, especially in the mid-20th century. The lunch box tin manufacturer not only contributed to practical dining solutions but also influenced children's culture, nostalgia, and branding.

Lunch boxes made from tin first gained popularity in the 1950s. Before this era, lunch boxes were typically made of cloth or paper, which, while lightweight, offered little protection to their contents. The introduction of tin brought numerous benefits these sturdy, durable containers could withstand the rigors of daily use and were much easier to clean. A lunch box made of tin also provided an efficient barrier against external elements, ensuring that food remained fresh and unspoiled.

The aesthetic appeal of tin lunch boxes contributed significantly to their success. Manufacturers started to produce these containers in various sizes, shapes, and colors, often featuring popular cartoon characters, movies, or television shows aimed at children. This marketing strategy transformed lunch boxes into collector's items, deeply embedded in nostalgic memories for those who grew up in households where such lunch boxes were a staple. Large corporations recognized this potential and began collaborating with lunch box manufacturers to produce themed items that appealed to children—bringing both lunch and leisure into the schoolyard.

lunch box tin manufacturer

As trends evolved, so did the production processes of lunch box tin manufacturers. In earlier times, the process of creating a tin lunch box involved manual craftsmanship, which could be labor-intensive and time-consuming. However, advancements in technology have revolutionized manufacturing techniques. Computer-aided design (CAD) allows for more intricate designs and customization, reducing production time and costs. These advancements have also expanded the range of eco-friendly materials available, as today’s manufacturers are increasingly conscious of environmental impacts and the importance of sustainability.

Moreover, the role of lunch box tin manufacturers transcends mere production; they are important players in global trade. As demand for unique and culturally relevant designs increases, manufacturers are now sourcing materials and labor from diverse regions, fostering cross-cultural exchanges. For instance, Asian manufacturers have become major players in producing lunch boxes for international markets, offering innovative designs that blend aesthetics and functionality.

Despite the evolution in manufacturing and changing consumer preferences, the lunch box remains a dependable companion for kids and adults alike. Today’s consumers are placing increasing importance on eco-conscious products, which is causing a resurgence in interest in tin lunch boxes as an alternative to those made from plastic.

In conclusion, the impact of lunch box tin manufacturers extends far beyond mere food transport. They have shaped cultural notions surrounding lunchtime, nostalgia, and childhood, while adapting to the shifting priorities of society. In this digital age, where convenience often trumps environmental considerations, these manufacturers have a unique opportunity to blend tradition with innovation, ensuring that lunch boxes remain an enduring element of our lives. As they embrace sustainable practices and modern designs, lunch box tin manufacturers will continue to play a vital role in popular culture and food preservation for years to come.

-

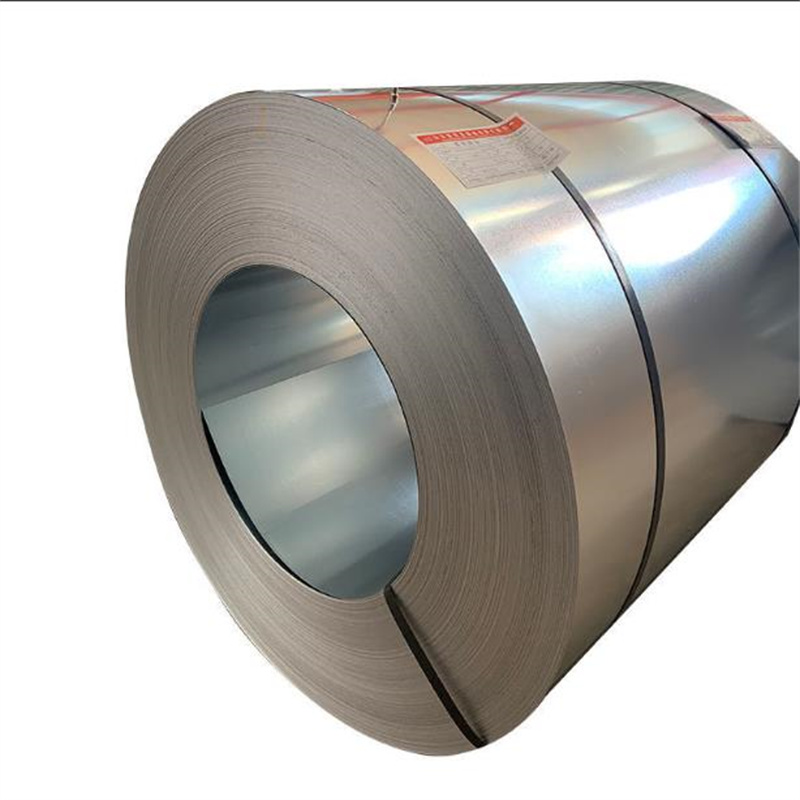

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

buy corrugated roof sheet end capping

NewsMar.07,2025