10 月 . 17, 2024 03:49 Back to list

Suppliers of Pre-Painted Galvanized Iron Sheets for Various Applications

The Growing Demand for Pre-Painted Galvanized Iron Sheets A Overview of Suppliers and Industry Trends

In the ever-evolving construction and manufacturing sectors, the use of pre-painted galvanized iron sheets (PPGI) has gained substantial traction. These materials are favored for their structural integrity, aesthetic appeal, and the protective qualities they offer. As industries look for innovative solutions to enhance both the functionality and appearance of their products, the demand for PPGI is on the rise, leading to an increasing number of suppliers entering the market.

Understanding Pre-Painted Galvanized Iron Sheets

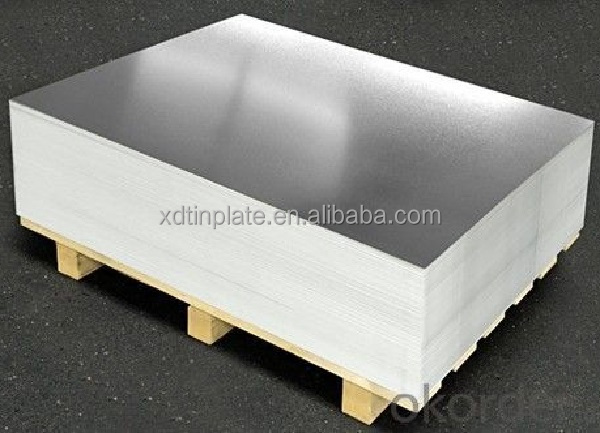

Pre-painted galvanized iron sheets are steel sheets that have undergone a galvanization process, where they are coated with a layer of zinc to enhance corrosion resistance. Following this, they are pre-painted with high-quality paints, which are formulated to withstand various environmental conditions. This process results in a product that not only protects against rust and degradation but also offers a variety of colors and finishes that can complement any architectural design.

The application of PPGI is vast. It is commonly used in roofing, wall cladding, and various household appliances due to its lightweight nature and high durability. Additionally, the pre-painting process means that projects can save time and costs related to painting on-site, enhancing efficiency.

The Suppliers Landscape

As the demand for PPGI continues to grow, so too does the number of suppliers in the market. These suppliers range from large multinational corporations to smaller, niche companies. The competitive landscape offers potential buyers a plethora of options, ensuring competitive pricing and diverse product offerings.

Reputable suppliers often provide detailed specifications about the materials, including information on the zinc coating thickness, paint quality, and the range of colors available. Furthermore, many evolve their offerings to include treatments that improve UV resistance and color retention, meeting the demands of customers looking for longevity and performance.

Factors Influencing Supplier Selection

When selecting a supplier for pre-painted galvanized iron sheets, several factors come into play

pre painted galvanized iron sheets suppliers

1. Quality Assurance Suppliers that adhere to international quality standards, such as ISO certification, are often preferred. Quality assurance ensures that the PPGI will withstand harsh weather conditions and maintain its aesthetic appeal over time.

2. Customization Options Many projects require specific sizes, colors, or finishes. Suppliers that offer customizable solutions are often more appealing to architects and builders who need tailored materials to meet design specifications.

3. Delivery and Logistics The ability to deliver products on time and manage logistics effectively can significantly influence supplier choice. Buyers often prefer suppliers with robust supply chains that can ensure timely delivery, particularly for large projects.

4. Customer Service Good customer service plays a crucial role in maintaining long-term relationships between suppliers and buyers. Suppliers who provide comprehensive pre and post-sales support are typically favored in the industry.

The Future of PPGI

The future of pre-painted galvanized iron sheets looks promising, driven by ongoing urbanization and infrastructure development. As construction companies increasingly focus on sustainability, the use of PPGI is projected to rise due to its long lifespan and recyclability. Suppliers are also beginning to prioritize eco-friendly production methods, much to the satisfaction of end-users who are increasingly environmentally conscious.

Moreover, technological advancements in coating processes and material treatments are expected to enhance the features of PPGI further, making it an even more attractive option for builders and manufacturers.

Conclusion

The landscape for pre-painted galvanized iron sheets suppliers is vast and dynamic, characterized by quality, diversity, and innovation. As the demand continues to grow, both established suppliers and new entrants will need to focus on providing high-quality products along with exceptional service to stay ahead in the competitive market. With its endless applications and benefits, PPGI is poised to remain a key component in the materials used for construction and manufacturing, offering both durability and visual appeal in various projects. As we look to the future, the evolution of this market segment will undoubtedly be shaped by the trends towards sustainable practices and advanced material sciences, driving the industry towards new heights.

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

buy corrugated roof sheet end capping

NewsMar.07,2025