9 月 . 14, 2024 13:17 Back to list

roof cap sheet manufacturers

Roof cap sheets are essential components in the construction and roofing industry, particularly for those seeking high-performing and durable roofing solutions. Manufactured by various suppliers, these sheets are designed to provide protection and improve the overall aesthetic of buildings. This article delves into the key aspects of roof cap sheet manufacturers, focusing on their products, techniques, and the importance of quality in the roofing sector.

Roof cap sheets are essential components in the construction and roofing industry, particularly for those seeking high-performing and durable roofing solutions. Manufactured by various suppliers, these sheets are designed to provide protection and improve the overall aesthetic of buildings. This article delves into the key aspects of roof cap sheet manufacturers, focusing on their products, techniques, and the importance of quality in the roofing sector.

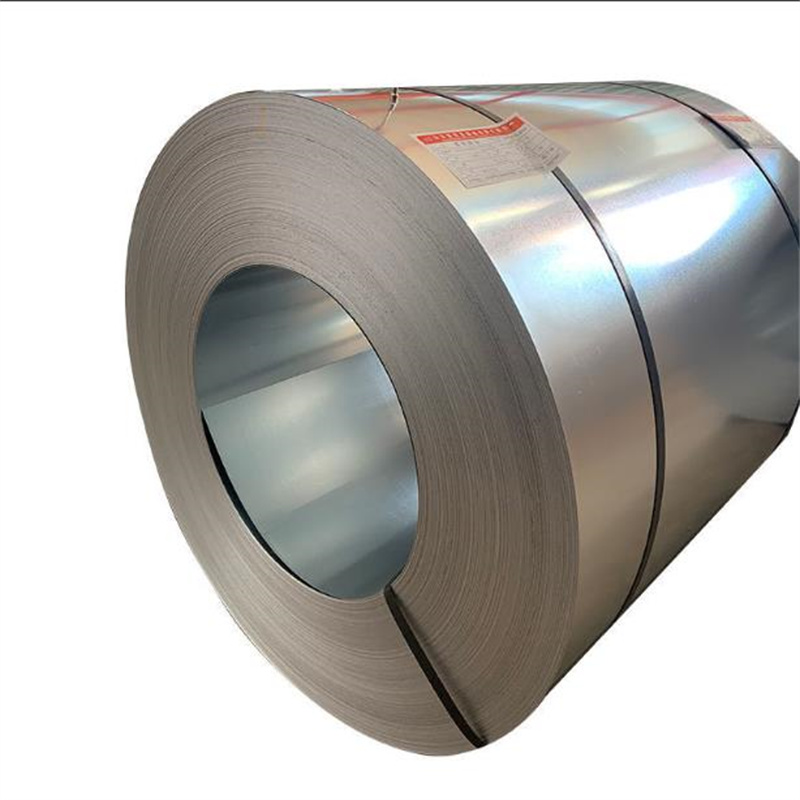

The range of materials used in roof cap sheet production varies widely. Common options include metal, fiberglass, and advanced polymer composites. Metal cap sheets, often made from aluminum or galvanized steel, are highly prized for their strength, lightweight properties, and resistance to corrosion. Fiberglass sheets, on the other hand, are favored for their excellent insulating properties and ability to withstand high temperatures. Manufacturers continually explore new materials and technologies to enhance performance and extend the lifespan of their products.

roof cap sheet manufacturers

Innovation plays a significant role in the operations of roof cap sheet manufacturers. Many have embraced modern fabrication techniques, such as automated cutting and precision manufacturing processes, which improve efficiency and reduce material wastage. Additionally, advancements in coatings and finishes allow manufacturers to produce cap sheets that perform better while offering an attractive appearance. Manufacturers are also increasingly focusing on sustainable practices, developing eco-friendly materials and processes that align with contemporary environmental standards.

Choosing the right roof cap sheet manufacturer is crucial for builders and architects. Clients should look for manufacturers that prioritize quality assurance, ensuring their products meet industry standards and local building codes. Reviews, certifications, and client testimonials can serve as valuable tools in making informed decisions. Reputable manufacturers often provide warranties for their products, further reflecting their commitment to quality and customer satisfaction.

In conclusion, roof cap sheets are indispensable elements in today's roofing systems, and selecting the right manufacturer is vital for achieving optimal performance and aesthetics. With the ongoing advancements in materials and technologies, the future of roof cap sheets looks promising. Quality manufacturers who invest in innovation will play a crucial role in shaping the industry, providing solutions that meet the diverse needs of modern architecture while ensuring durability and protection against the elements.

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

buy corrugated roof sheet end capping

NewsMar.07,2025