10 月 . 22, 2024 10:45 Back to list

Wholesale Color Coating Plant Factories for Galvanized Products and Services

The Rise of Wholesale Galvanized Color Coating Plants Transforming the Metal Industry

In the contemporary industrial landscape, the demand for durable, aesthetically pleasing, and corrosion-resistant metal products has surged. This trend has propelled the establishment of wholesale galvanized color coating plants—facilities dedicated to enhancing the qualities of metal surfaces through advanced coating technologies. This article explores the significance, operations, and benefits of these plants, illuminating their critical role in transforming the metal industry.

Understanding Galvanization and Color Coating

Galvanization is the process of applying a protective zinc coating to steel or iron to prevent rusting. This method has been a standard in metal protection for decades, ensuring longevity and reliability in various products, from construction materials to automotive components. However, the standard galvanized finish may not meet the aesthetic demands of modern consumers, leading to the development of color coating technologies.

Color coating is an added layer typically done after galvanization, offering a spectrum of colors, finishes, and textures. This process not only enhances the visual appeal of metal products but also adds extra protection against environmental factors. Thus, wholesale galvanized color coating plants strive to provide a comprehensive solution to manufacturers looking to meet both functional and aesthetic needs.

The Operations of Wholesale Galvanized Color Coating Plants

A typical wholesale galvanized color coating plant operates through a series of carefully controlled processes. Initially, raw steel or iron products undergo surface preparation, which is crucial for optimal adhesion of the zinc and subsequent coatings. This may involve cleaning, degreasing, or even shot blasting to remove any contaminants.

Following surface preparation, the metal is subjected to hot-dip galvanization, where it is dipped into molten zinc at high temperatures. This creates a robust layer that protects against corrosion. Once galvanization is complete, the color coating process begins. Various methods such as powder coating, liquid coating, or electrostatic spraying can be employed, each offering distinct benefits depending on the desired outcome.

After applying the color coat, curing is essential to ensure durability. The coated products are then passed through curing ovens, where heat solidifies the coating, resulting in a hard and long-lasting finish. The final step involves inspection and quality control to ensure every piece meets the required standards before being sent to wholesalers or manufacturers.

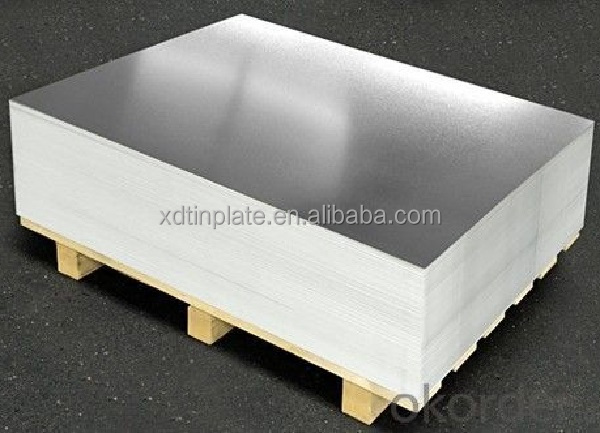

wholesale galvanized color coating plant factories

Benefits of Wholesale Galvanized Color Coating Plants

1. Aesthetic Appeal One of the most significant advantages of color-coated galvanized products is their enhanced visual appeal. Customers now can choose from a variety of colors and finishes, allowing them to achieve a polished look that complements their projects.

2. Durability The combination of galvanization and quality coatings significantly improves resistance to corrosion, UV rays, and environmental damage. This durability translates into lower maintenance costs and longer service life for products.

3. Eco-Friendly Options Many modern color coating processes utilize eco-friendly materials and techniques. Manufacturers are increasingly adopting environmentally friendly practices, which are essential in today's regulatory climate.

4. Customization Wholesale galvanized color coating plants offer a wide range of customization options. This flexibility enables clients to specify exact colors, textures, and finishes, tailoring products to fit their unique specifications.

5. Streamlined Supply Chain By consolidating the processes of galvanization and color coating under one roof, wholesale plants can provide manufacturers with a streamlined supply chain. This capability not only reduces lead times but also enhances efficiency and communication between parties.

Conclusion

Wholesale galvanized color coating plants are playing a pivotal role in the evolution of the metal industry. By merging the protective benefits of galvanization with the versatility and beauty of color coatings, these facilities deliver products that meet the high standards of both functionality and aesthetics demanded by modern consumers. As industries continue to evolve and embrace innovative technologies, the importance of such plants will only grow, paving the way for more resilient and visually appealing metal products.

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

Galvanized steel sheet price hot-dip galvanized

NewsMar.07,2025

-

buy corrugated roof sheet end capping

NewsMar.07,2025